Falling to Pieces: The near crash of Aloha Airlines flight 243

Note: this accident was previously featured in episode 13 of the plane crash series on December 2nd, 2017, prior to the series’ arrival on Medium. This article is written without reference to and supersedes the original.

On the 28th of April 1988, passengers aboard an Aloha Airlines Boeing 737 stared death in the face when the roof ripped off their plane at 24,000 feet. Battered by hurricane-force winds and freezing temperatures, the passengers and crew lived on a knife’s edge for thirteen terrifying minutes, the plane’s buckling floor beams the only assurance against certain annihilation. And yet, by some stroke of fortune, the plane held together long enough for the crew to make a harrowing emergency landing on the island of Maui, saving 94 lives, at the cost of only one — that of veteran flight attendant Clarabelle Lansing, who vanished without a trace into the big sky she knew so well.

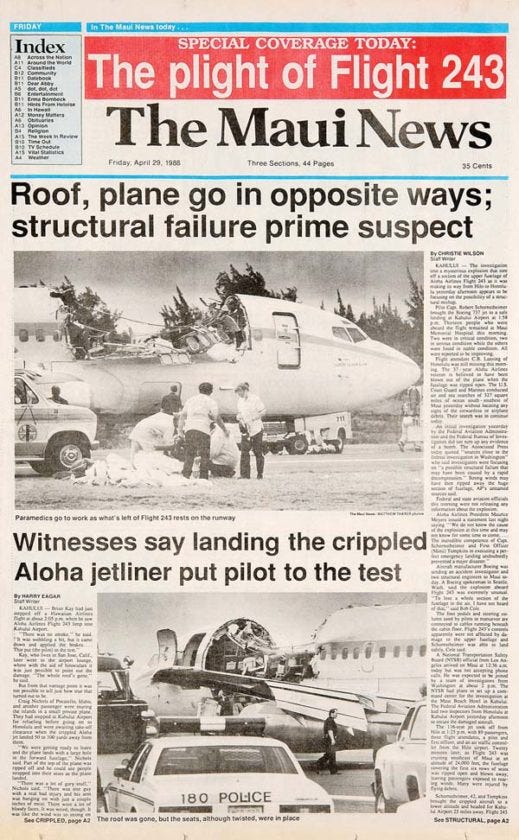

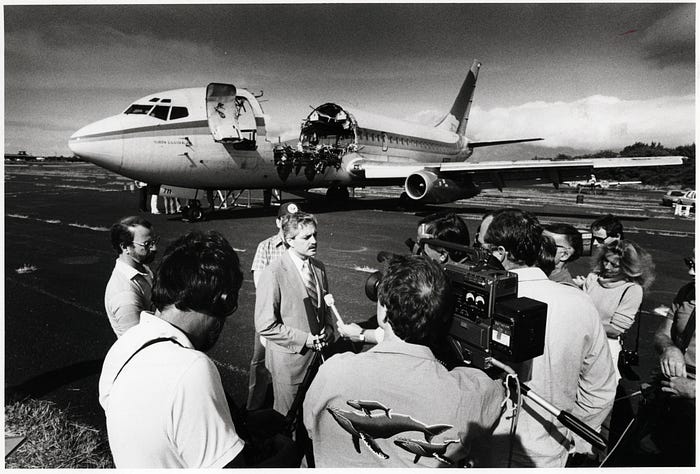

Pictures of the badly damaged 737 and its equally battered occupants quickly spread around the world. The accident played into many nervous flyers’ worst nightmares, and helped plant the idea of catastrophic explosive decompression into the popular consciousness. But it also caused investigators and regulators to take a long hard look not just at Aloha Airlines, but at the way the industry as a whole approached the growing number of planes which were operating beyond their expected service lives. Their conclusions were inescapable: America was not doing enough to maintain its aging airplanes. And in the aftermath of the near crash of Aloha Airlines flight 243, that lesson would indeed be learned, as the Federal Aviation Administration launched a long-overdue revolution in aircraft maintenance which would eventually affect everyone who flies.

◊◊◊

More so than in almost any other place in the United States, the residents of the Hawaiian Islands depend on air travel in their day-to-day lives. Thousands of Hawaiians work and live on different islands, creating a steady market for short-haul commuter flights that has sustained many unique and fascinating airlines over the years. Airplanes flying in Hawaii also see heavier utilization than almost anywhere else in the world, and for many years, the undisputed champion in this area was Aloha Airlines, a scrappy commuter carrier whose orange and white planes were a common sight on the islands from the company’s founding in 1946 to its closure in 2008.

The core of Aloha Airlines’ fleet throughout most of its existence consisted of around a dozen first generation Boeing 737–200s, known for their stubby fuselages and tiny, cigar-like engines. These were the planes which spent their days hopping back and forth between the islands, fulfilling routes so short that they averaged nearly three complete flights every hour for years on end.

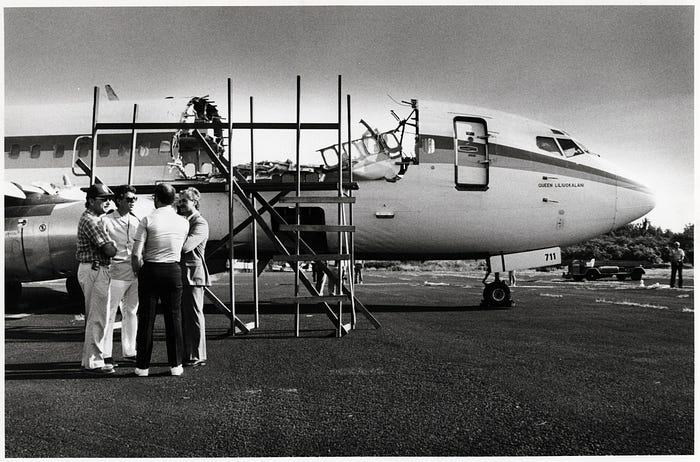

However, the speed at which an airplane begins to suffer from the ravages of old age depends not on how old it is, but on how many flight cycles it has endured, and so it was significant that by 1988 the Aloha Airlines Boeing 737–200 registered N73712 had the most cycles of any 737 in the world, clocking in at over 90,000 flights. Her sister ship, N73711, nicknamed “Queen Liliuokalani,” was not far behind, with 89,680 cycles accumulated by April 1988, putting it in second place worldwide.

It was on the 28th of April that year that “Queen Liliuokalani” departed for another full day of island-hopping flights. The first six flights of the day passed uneventfully, save for the constant rattling noises emanating from the aging airframe, which had become so commonplace that for some frequent fliers they might have been more comforting than alarming. Her crew and passengers could not have been aware that the seventh flight would be her last.

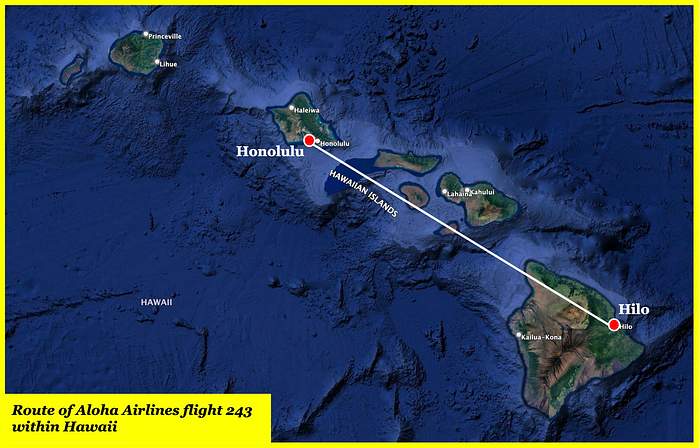

The seventh trip that day was flight 243 from Hilo on the Big Island of Hawaii to Honolulu on the island of Oahu, an utterly unremarkable trip that this airplane had completed hundreds if not thousands of times before. In command were Captain Robert “Bob” Schornstheimer and First Officer Madeline “Mimi” Tompkins, both of whom had over 8,000 flight hours and plenty of experience on the 737. They were joined by three flight attendants, 89 passengers, and an air traffic controller who was riding in the cockpit jump seat, totaling 95 people on board. None of them knew that something was terribly wrong — save for one passenger, who thought she saw a crack to the right of the entry door as she was boarding. Was it a big deal? She had no idea, and she didn’t want to bother the crew, so she said nothing, preferring to believe that the airline knew better than she did.

Flight 243 took off from Hilo at 13:25, climbing toward its cruising altitude of 24,000 feet, where it would stay only briefly before descending into Honolulu. The crew seemed relaxed, idly pointing out landmarks as they approached the island of Kaho’olawe. In the cabin, although the fasten seatbelt sign was still on, the flight attendants were already serving drinks, standard practice at Aloha Airlines because the flights were so short. None of them would forget where they were standing: Michelle Honda in economy, Jane Sato-Tomita near row 2, and lead flight attendant Clarabelle “CB” Lansing at row 5. Lansing was handing a drink to a passenger, reaching out across the aisle — and then there was a huge explosion, and in the blink of an eye she was gone.

In a fraction of a second, a hole opened up in the left side of the fuselage, and the entire wall split open from row 1 all the way to row 6. The breach instantly raced up and over the top of the plane, then down to window height on the opposite side, before peeling backwards and ripping away, ejecting 35 square meters of fuselage and interior panels into the sky 24,000 feet above the Pacific Ocean. Debris slammed into the wings, engines, and tail, careening off every forward-facing surface in a hail of flying metal. Air rushed out of the cabin as the inside and outside pressure violently equalized, blowing away everything that wasn’t nailed down. The floor near the first several rows buckled upward as air forced its way out of the cargo hold, and the cockpit door was blasted straight off its hinges. Passengers were pulled forward, the air literally expelled from their lungs, only to be slammed back into their seats again as air rushed back into the void at 400 kilometers per hour. The explosion and the subsequent decompression were so violent that many passengers initially believed the plane to have disintegrated in midair.

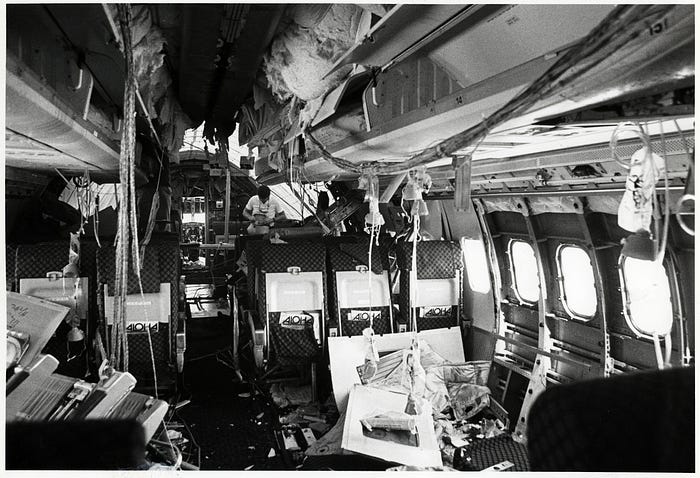

Within seconds, however, it became apparent that against all odds the plane was still flying. The roof and walls had vanished along the entire section stretching from the main cabin door all the way back to the leading edge of the wings, leaving six rows of seats completely open to the air. Passengers hung precariously above the Pacific, saved only by their seat belts, battered by hurricane force winds and freezing temperatures amid the rarefied air at 24,000 feet. The flight attendants were also in dire straits, as №2 stewardess Jane Sato-Tomita had been struck in the head and thrown to the floor under a pile of debris, where she lay unconscious and bleeding in the middle of the open-air first class section.

Her colleague Michelle Honda, who had been near the tail section, managed to hold onto the metal bars under the chairs as the decompression knocked her to the ground, escaping serious injury. She was the first to try to respond to the emergency; believing a crash landing to be imminent, she got up and screamed at the passengers to put on their life vests, struggling to be heard over the indescribable noise. All around her, passengers reached for their oxygen masks, desperate for air, only to find that there was none — the oxygen delivery system had been destroyed.

In the cockpit, the pilots too were caught completely by surprise. The cockpit voice recording captured a huge bang followed by a furious roar, pierced only by the sound of screaming. As the floor bent downward under the sudden redistribution of weight, the cockpit dropped more than one meter relative to the body, snapping five crosswise floor beams and cracking several others. And yet the cockpit did not break away, instead hanging precariously in place by the sheer tensile resilience of the floor.

Regaining his senses, Captain Schornstheimer looked back to find that the cockpit door was missing and he could see a patch of blue sky where the first class cabin ceiling had been. Realizing that they were in a very serious emergency, he took over control of the plane from First Officer Tompkins and initiated an emergency descent. Hurtling down through the sky at 290 knots, descending at around 4,000 feet per minute, the noise was so extreme that the pilots could not hear each other speak, and Schornstheimer was forced to convey his intentions by hand signals only. It would later be noted that such a high speed descent, although prescribed in the emergency procedures, could have caused the badly damaged plane to break apart — but, unaware of the extent of the destruction, the pilots didn’t know any better.

In the cabin, the steep emergency descent — intended to get the passengers to breathable air as quickly as possible — felt and looked a lot more like an uncontrolled dive toward the ocean below. Clawing her way forward against the wind, surrounded by screaming passengers, Michelle Honda managed to reach the unconscious Jane Sato-Tomita, but was unable to pull her free of the wreckage.

In front of them, the cockpit was sagging so dramatically and the damage was so extensive that it was difficult to tell whether the pilots were still in control of the plane. As she struggled to help her colleague, a passenger asked Honda whether the cockpit was still attached at all, and she realized with sudden horror that she didn’t know the answer. What if the pilots had been sucked out in the explosive decompression? Training didn’t cover anything about this scenario. Hurrying to the rear of the plane, Honda grabbed the interphone and attempted to contact the crew, but the phone line had been severed, and her desperate calls were met with silence. In a moment of panic — one she says she struggled to understand later — she actually asked a nearby passenger whether he knew how to fly a plane!

Up front, First Officer Tompkins set the transponder to squawk the emergency code 7700 and attempted to contact Honolulu air traffic control. Over and over she called out, “Center, Aloha two four three!” But there was no reply.

In Honolulu, the air traffic controller on duty spotted on radar what appeared to be an Aloha Airlines 737 squawking 7700 and descending rapidly. The plane seemed to be veering toward the island of Maui, so he called his counterpart at Kahului Airport and warned him of the inbound emergency, even though neither center had established contact with the crew.

At around 13:48, three minutes after the explosion, the pilots managed to make contact with the Maui tower, but the wind noise was so extreme that neither could hear what the other was saying. It took another minute for First Officer Tompkins to get her message across. “Maui tower, Aloha two forty three!” she said again. “Maui tower, Aloha two forty three, we’re inbound for landing!”

“Calling tower, say again?” the controller replied.

“Maui tower,” Tompkins said, straining to make herself heard, “We’re inbound for landing, we’re just to the west of Makena — just to the east of Makena — descending out of thirteen and we have rapid depr — we are unpressurized, declaring an emergency!”

“Is that Aloha two forty four on the emergency?” the controller asked, still hearing a cacophony of static every time Tompkins tried to speak.

“Aloha two forty three!”

“Aloha two four three, say your position,” said the controller.

“We’re just to the east of Makena Point, descending out of eleven thousand,” she replied. “Request clearance into Maui for landing… request the equipment…”

“Okay, the equipment is on the fi — is on the way,” the controller stuttered.

As the plane neared 10,000 feet, Captain Schornstheimer reined in the descent, causing the plane to slow down and the noise to decrease. At the same time, he began to navigate around the south side of the island, where the blackened summit of Haleakala rose to 11,000 feet just a few miles to the right. As the plane started to level off and turn, passengers realized that somebody was in control, and desperation began to turn into a faint hope that maybe, just maybe, they would make it.

Taking off her oxygen mask, Tompkins turned to Schornstheimer and asked, “Do you want me to call for anything else?”

“Nope,” the Captain replied.

At 13:51, Tompkins informed the controller, “Maui tower, two forty three, it looks like we’ve lost a door, we have a hole in this, uh, left side of the aircraft.” They also had a hole in the right side, and a hole in the top, but she could only report what she could see from her seat.

A minute went by without a reply. “Aloha two forty three, you still up?” the controller eventually asked.

“Affirmative!” Tompkins replied.

As the plane made its final turn toward Kahului Airport, the passengers and crew fought to hold on just a few more minutes against the biting wind, flailing wires, and swirling debris, hoping against hope that the floor beams would hold. In the back of the plane, numerous passengers joined hands in prayer, while others tried to will the airplane to stay together, fearing that it would snap in two at any moment.

“Want the gear?” Tompkins asked. “Do you want it down?”

“Flaps fifteen landing,” Schornstheimer shouted.

“Okay!”

“Here we go!”

On Schornstheimer’s prompting, Tompkins contacted the tower and said, “Ah, we’re gonna need assistance, we cannot communicate with the flight attendants — we’ll need assistance for the passengers when we land.”

“Okay, I understand you’re gonna need an ambulance, is that correct?” the controller asked.

“Affirmative,” said Tompkins.

Meanwhile, Schornstheimer was finding that the damage to the floor and the bending frame were doing strange things to the flight control cables. The plane felt simultaneously mushy and springy, and he didn’t always get the response he was expecting. “Feels like manual reversion!” he shouted.

“Well, we could [unintelligible] the hole,” said Tompkins.

“I know it, yeah.”

“Can we maintain altitude okay?” Tompkins asked.

“Let’s try flying with the gear down here,” Schornstheimer suggested.

“Alright, you got it.” Tompkins reached over and moved the gear lever to the down position. The pilots heard the familiar rumble of the landing gear lowering, but the light which indicated that the nose gear was locked didn’t come on. Strangely, neither did the “gear unsafe” light.

“Okay and uh, just to verify, you broke up initially, you do need an ambulance, is that correct?”

“They still don’t understand!” Tompkins said to Schornstheimer. Keying her mic again, she shouted, “Affirmative!”

“Roger, how many do you think are injured?”

“We have no idea, we cannot communicate with our flight attendants,” Tompkins said.

“Okay, we’ll have an ambulance on the way,” the controller replied. But he immediately became distracted and forgot to call the ambulance.

“There’s a possibility that we won’t have a nose gear!” Tompkins added.

“Tell him we got such problems but we are going to land anyway, even without a nose gear,” Schornstheimer said. “But they should be aware of… we do not have a safe nose gear down indication.”

With the cockpit already hanging by a thread, landing without the nose gear might well have been a death sentence for the pilots, but they had no choice — at any second the plane could break apart, and staying in the air longer to confirm the gear position was out of the question.

Tompkins now attempted to extend the flaps to the landing position of fifteen degrees, but Schornstheimer found that when she did so, his control difficulties increased significantly. The plane was shaking and rocking alarmingly, and his inputs were becoming less and less effective.

“Is it easier to control with the flaps up?” Tompkins asked.

“Yeah, put ’em at five,” Schornstheimer said. It was decided; they would land with a lower flap setting and a higher speed than normal.

As flight 243 entered its final approach, the failures continued to compound. The plane yawed slightly, and Captain Schornstheimer looked down to discover that the left engine had failed. He tried placing the left engine start switch to the “flight” position, but the engine didn’t respond. With the runway in sight and his eyes on the prize, he decided it didn’t matter — they would land on one engine, or none, if it came to that.

Spotting the incoming plane, airport personnel literally dropped to their knees in shock. The 737 looked like a seal after a shark attack, as though some horrifying bird had taken a huge bite out of it and flown away. The sight simply defied comprehension. But the controller did think to give the crew some good news: “Aloha, two four three, just for your information, the gear appears down,” he said.

In the cabin, passengers counted down the seconds to landing. Five, four, three, two…

And then, at 13:58 and 42 seconds, thirteen minutes after the explosion, Aloha Airlines flight 243, or what was left of it, touched down on runway 02 at Kahului Airport. The plane eased down onto its nose gear; the fuselage bent a little bit in the middle, but the gear held. Captain Schornstheimer applied the brakes and First Officer Tompkins deployed the thrust reverser on their one good engine. And before the disbelieving eyes of the firefighters, the crippled 737 rolled to a safe halt on the runway, rows of bloodied passengers visible through the gaping hole where the first class cabin used to be. Somehow, against all odds, they had made it.

The relief which the passengers felt at that moment must have been indescribable. But not everyone was out of the woods: several people were severely injured, including flight attendant Jane Sato-Tomita, who was still unconscious, suffering from a concussion and several severe head lacerations. Farther back, an 84-year-old woman had been hit by debris, fracturing her skull in multiple places, and numerous passengers were suffering from head injuries, puncture wounds, wind burns, and a variety of other painful side effects of the extreme conditions on board the plane. Many of them were able to exit the plane on their own, sliding down to kiss the solid earth, but some had to be helped out on stretchers, a task which was complicated by the fact that ambulances still had not arrived. In fact, the controller only called for one around the time the plane touched down, and when it showed up seven minutes later, its crew discovered a scene of complete pandemonium, with dozens of people in urgent need of medical attention. In all, 65 people were injured, eight of them seriously. There weren’t enough ambulances on the whole island of Maui to transport them all, and several had to be rushed to hospital in private vans.

It was only after landing that the crew was able to confirm one horrid, gnawing suspicion: flight attendant CB Lansing was missing. She had been standing right in the area where the roof opened up, and at the moment of the explosion, several passengers saw her fly up and to the left before disappearing from view. A bloodstain on the outside of the plane aft of the breach testified to her violent end. It was difficult to imagine: the beloved 37-year veteran stewardess, who had been flying with Aloha Airlines since she graduated from high school in 1951, really was gone, presumed lost at sea. The United States Coast Guard spent three days searching for her in the waters off Kaho’olawe, but in the end neither CB Lansing nor the missing fuselage section were ever found.

As pictures of the badly damaged plane made their way onto the front pages of newspapers around the world, the National Transportation Safety Board dispatched a team of investigators to Hawaii to try to piece together why Aloha Airlines flight 243 almost came apart in flight. They expected that this would be a difficult task: after all, the failed fuselage section had fled the scene, and none of the original failure surface remained around the edges of the hole. But as it turned out, the exact origin point didn’t really matter: the entire fuselage of “Queen Liliuokalani” was so riddled with corrosion, fatigue cracks, and repair patches that it was a wonder it held together as long as it did. In some areas, nearly every rivet hole had a fatigue crack emanating from it. How could things have ever gotten this bad?

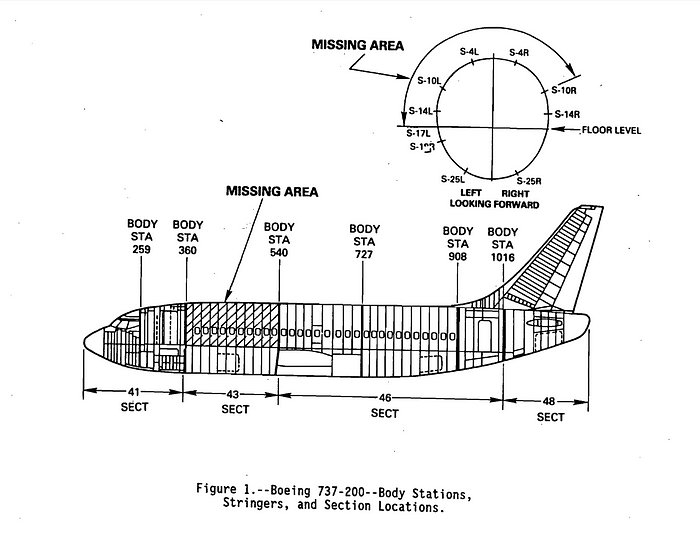

To explain why the fuselage had ended up in such a sorry state, it helps to go back to the most basic principles upon which it was designed. The fuselage of the 737 is made up of aluminum sheet metal panels arranged circumferentially around a frame, with each panel overlapping the one below it by about 7.6 cm (3in). These sheets themselves were only 0.9 millimeters (0.036in) thick, somewhat less than the skin thickness of previous aircraft. Boeing had opted for this thin skin in order to save weight, but the company was well aware that reducing the thickness of the skin could also make it more vulnerable to metal fatigue.

The problem is that the fuselage of an airplane is not static: every time the cabin is pressurized, the skin is placed under stress, which is then removed at the end of the flight. This constant back-and-forth movement causes the metal to slowly break down over time, developing fatigue cracks which can eventually escalate to the point of catastrophic failure if not caught in time.

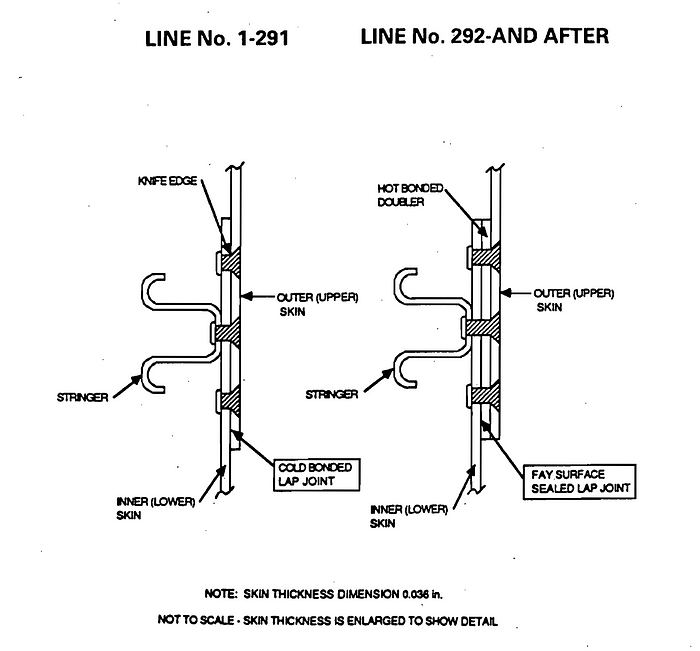

The weak points for fatigue on the 737 fuselage were the junctions between the sheets of aluminum skin, known as lap joints. Consequently, Boeing developed a bonding process for the lap joints which would help the entire skin absorb stress as a single unit, improving its resistance to fatigue despite its lack of thickness. On the very first 737s, Boeing used a cold-bonding epoxy, which was kept in dry ice, then applied to an etched bonding surface at each lap joint. The epoxy would then cure in place, holding the panels together across a large, continuous joint that would distribute stress more evenly, preventing the development of cracks. Finally, following the epoxy application, three rows of rivets were punched through each lap joint to attach the skin to the aircraft’s frame.

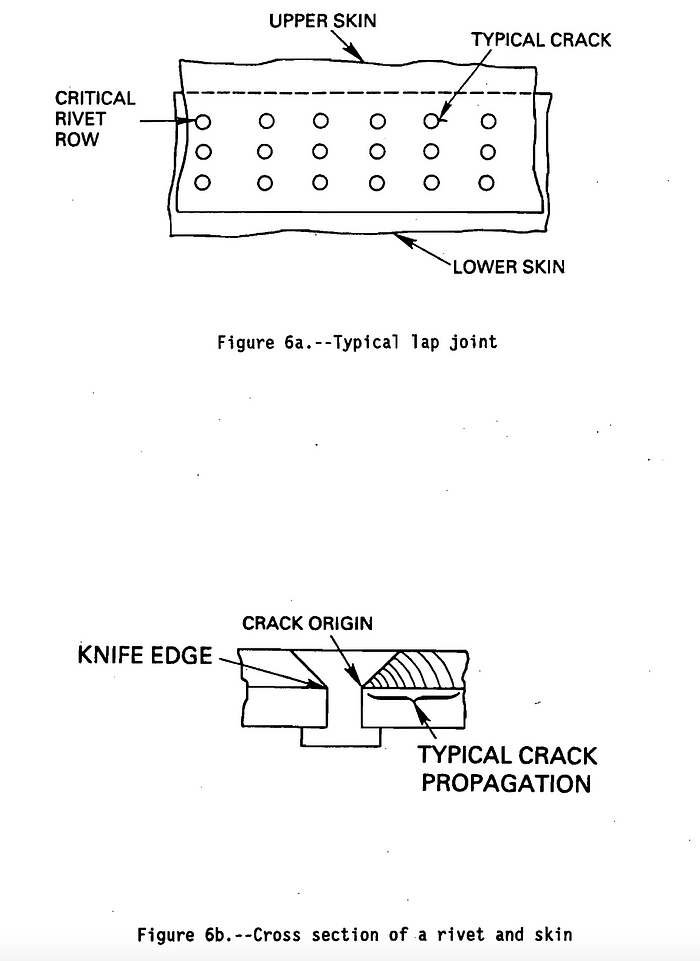

Boeing had built 291 737s this way before discovering that there were serious flaws in the process. The etched fuselage plates didn’t always provide a good bonding surface for the adhesive, causing it to delaminate from one or both panels. This could also happen if there was too much condensation on the cold epoxy, or if the epoxy was left exposed to higher temperatures for too long before being applied, causing it to cure prematurely. The result was that every early Boeing 737 had incomplete bonds at random locations in their various lap joints. Once in service, water could enter these incomplete bonds, degrading the epoxy and causing corrosion of the metal. Over time the lap joints could disbond completely, transferring pressurization stresses through the rivets instead. If this occurred, the design of the rivets tended to exacerbate the problem. Because the early 737s used rivets whose heads sat flush with the surface instead of protruding beyond it, the underlying skin featured a “knife edge” that could easily crack under stress, as shown in the above diagram. This would initiate fatigue cracks that could then spread down the row of rivets in both directions.

After becoming aware of this problem, Boeing ended the use of cold-bond epoxy in 1972, and all Boeing 737s from frame #292 onward were produced with a hot bonding method which was less prone to errors. However, the already existing airplanes could not simply be reconstructed using the new method, and Boeing needed to develop ways to keep them structurally sound. One of the affected aircraft was frame #152, produced in 1969 and sold to Aloha Airlines, where it became N73711 “Queen Liliuokalani.” Her sister ships N73712, N73713, and N73717 were affected as well. On these airplanes, the only solution was to instate a robust monitoring program to catch and repair corrosion and fatigue cracks before they could become dangerous. In 1970 and again in 1972, Boeing issued service bulletins to all 737 operators with instructions for how to do this.

Aloha Airlines was especially vulnerable to this problem for a number of reasons. First, operating in a tropical environment tended to accelerate corrosion on its aircraft. And second, the airline’s extremely short legs caused its planes to accumulate flight cycles at twice the rate that Boeing had anticipated. The 737–200 was designed with a service life of 20 years and/or 75,000 flight cycles, but by the time they were 19 years old, three Aloha Airlines 737s had already significantly exceeded this threshold, including “Queen Liliuokalani.” This put Aloha Airlines at the vanguard of the 737 fleet, where it kept pushing its airplanes deeper into uncharted territory in terms of structural integrity.

Boeing had been able to prove that the 737’s fuselage skin met regulatory standards for fatigue resistance by pressurizing half of a fuselage 150,000 times without observing any fatigue damage. But this impressive result could only be achieved in laboratory conditions, where the lap joint bonds were all perfect. In practice, the poor lap joint bonding on early 737s reduced this lifetime significantly, and it was not clear that all operators appreciated just how dangerous this problem could be. Indeed, it had already manifested once with fatal results. On the 22nd of August 1981, a Boeing 737–200 operating Far Eastern Air Transport flight 103, a domestic flight within Taiwan, suffered a failure of a lap joint in the fuselage skin underneath the first class cabin. A large section of the lower fuselage ripped away, the cockpit bent downward under the load, and the floor beams failed in compression, causing the aircraft to break up in midair over Sanyi township. All 110 passengers and crew were killed in the horrific accident. The cause? Undetected corrosion in disbonded lap joints leading to fatigue cracking of the fuselage skin, the exact problem Boeing had warned about 11 years earlier. And that plane had only 33,000 cycles, much less than that accumulated by most of the 737s at Aloha Airlines.

In 1987, the Federal Aviation Administration again raised the alarm about the problem after receiving reports of large cracks found in several 737–200s in the 40,000- to 50,000-cycle range. In response to the reports, the FAA issued a mandatory airworthiness directive (AD) requiring operators of early model 737s to implement the extra inspections called for in the 1972 Boeing service bulletin. Aloha Airlines received this AD and subsequently conducted visual inspections of its 737s, including “Queen Liliuokalani,” resulting in several minor repairs. But the AD also called for the lap joints to be inspected using the eddy current technique, in which an electric current is introduced to the metal, allowing specialized equipment to “see” cracks which may be too small for humans to detect. In fact the airline never conducted this required inspection on “Queen Liliuokalani,” and a series of cracks growing along a lap joint just above the windows on the left side of first class went undetected. The FAA followed this up with another AD requiring the replacement of certain original rivets with protruding head fasteners that would not create a knife edge where fatigue could take hold, but Aloha Airlines never did this either.

The airline’s regular inspections were also inadequate to stay on top of the fatigue problem. Inspections of a transport airplane were divided into A-checks, B-checks, C-checks, and D-checks, in descending order of frequency, with the heaviest structural inspections consigned to the D-check due to the slow rate of development of most structural issues. Boeing recommended that 737s undergo a D-check every 20,000 flight hours, and Aloha Airlines had proactively opted to do them at 15,000 hour-intervals, or approximately every eight years. However, because Aloha’s 737s flew such short flights, they accumulated more cycles in 15,000 hours than Boeing had expected in 20,000. And because fatigue of the fuselage is based on cycles, not hours, this meant that Aloha Airlines was actually inspecting its fuselages for structural issues at a significantly less frequent interval than that assumed by Boeing.

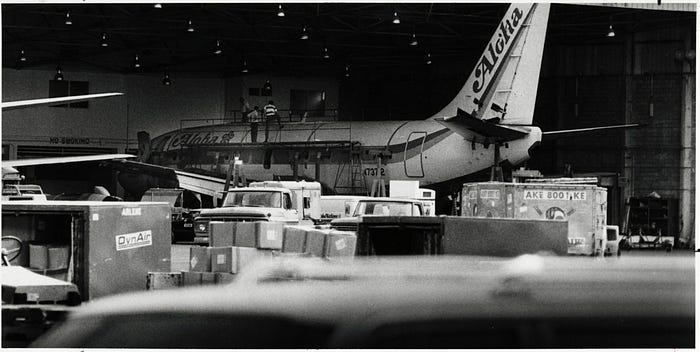

Furthermore, Aloha Airlines’ operating schedule left little room for comprehensive inspections. In fact, because the airline did not have any spare airplanes to pick up the slack if one had to be on the ground for an extended period, Aloha had decided, with FAA approval, to split its D-checks into eight major inspection blocks with 52 discrete steps, each of which could be accomplished independently while the plane was on the ground between flights. Inspectors would complete their tasks a few at a time at odd hours of the night, working under the incandescent hangar lights during the worst part of the human circadian low, trying not to fall asleep as they searched for minute cracks around hundreds of identical rivet holes. They did identify some cracks this way — after the accident, the NTSB found at least 24 places where mechanics had patched over cracks on the fuselage of “Queen Liliuokalani” — but they missed literally hundreds of others.

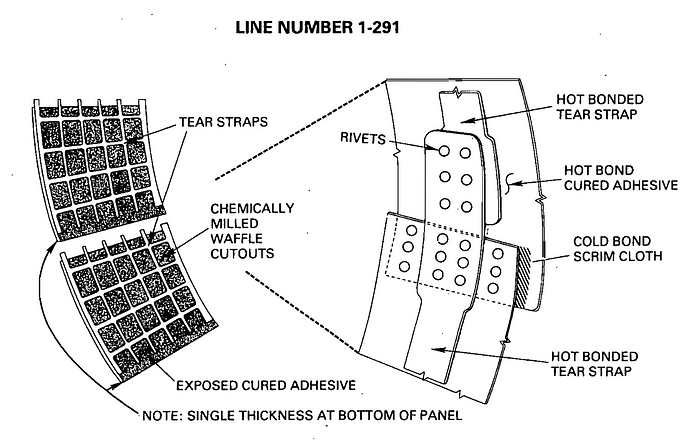

To prove their point, the NTSB conducted a thorough examination of a small piece of fuselage skin from the failed region which had embedded itself in the leading edge of the right wing during the accident (shown above). Upon conducting an eddy current inspection on this scrap of aluminum, they found at least five fatigue cracks which had been growing for more than 20,000 cycles and should have been easily detectable using available methods. The rest of the fuselage was in an equally calamitous state of disrepair, with so many cracks that it seemed to be held together by sheer force of will. And in addition to N73711 “Queen Liliuokalani,” which was obviously damaged beyond repair, inspections revealed that N73712 and N73713 also had such extensive corrosion and fatigue cracking that they could not be economically repaired, and both planes were immediately removed from service and scrapped. N73717 was in only marginally better condition, requiring one year of heavy repairs before it could safely return to service.

The NTSB believed that the sheer scale of the fatigue cracking on “Queen Liliuokalani” allowed the failure to bypass a built-in safety feature of the pressure vessel. The skin of the 737 is fitted with “tear straps” attached to the fuselage skin at 25-centimeter (10-inch) intervals, forming a grid of 25 by 25 squares which should redirect a breach and prevent it from spreading to adjacent squares. However, the tear strips were designed primarily to limit damage caused by debris impacts during an uncontained engine failure, and were not necessarily capable of stopping slow-moving fatigue cracks. Furthermore, corrosion had caused some of the tear straps to disbond from the skin, and the extent of the deterioration was such that dozens of separate cracks could have linked up across several 25 by 25 squares. The NTSB believed that this was what happened to Aloha Airlines flight 243: as the ill-fated flight reached its cruising altitude, the peak application of pressure caused several large cracks to join together until they all failed simultaneously, ripping off a huge section of the fuselage without regard for the tear straps.

Although the exact mechanism is fairly esoteric, and perhaps even unimportant, there are alternate theories. Long after the investigation ended, pressure vessel engineer Matt Austin proposed a somewhat more grotesque alternative explanation. In his view, the tear straps could have worked as intended, but if flight attendant CB Lansing was sucked into the resulting hole, her body could have temporarily blocked it, creating a “fluid hammer.” In effect, the sudden blockage of the outlet would have caused a transitory pressure spike — a fluid hammer — which overloaded a large section of the surrounding fuselage, leading to the catastrophic failure. The NTSB has acknowledged that the theory is possible, but the evidence for its original theory appears to be stronger, despite the fluid hammer’s understandable salience in popular culture.

Ultimately the NTSB could not say with certainty how and where the failure began, except that it must have been above the window line, and probably near row 3, where the floor buckled upward the most. This was also near where a passenger saw a crack while boarding the flight, and where cracks had previously been identified on other 737–200s. But it could find the exact cause of the engine failure on final approach — a secondary problem which further highlighted the sorry state of maintenance at Aloha Airlines. Although both engines had ingested debris, there was no appreciable loss of power as a result; it was only much later that the left engine quit. It turned out that the cables connecting both engines to the throttle quadrant were severely corroded, to an extent way beyond what could be considered safe. When the left side of the cabin floor buckled upward, it put extra stress on the left engine throttle cable, which ran through the floor; under this stress, the corroded cable eventually snapped. If the right side of the floor had also buckled upward, the right engine could have failed for the same reason, leaving the flight with no power on final approach — a scenario which was thankfully avoided.

Indeed, the scale of Aloha Airlines’ maintenance deficiencies boggles the mind. Across all of its D-checks, Aloha Airlines never made a single adverse finding, despite the fact that an NTSB inspection of the fleet revealed “considerable evidence of corrosion…swelling and bulging of the skin (pillowing), dished fastener heads, pulled and popped rivets, and blistering, scaling, and flaking paint…along the lap joints of almost every airplane.” Equally concerning, service bulletins and airworthiness directives had not been properly complied with — probably because Aloha Airlines didn’t have an engineering department and employed no qualified engineers. Instead, the Quality Assurance department handed the bulletins and directives directly to poorly trained inspectors who did not have the specialized education required to interpret them.

In fact, most of the airline’s maintenance inspectors had two hours or less of formal training before starting their jobs, and received no training on how to correctly perform various types of non-destructive inspections. All things considered, there was no one at the company who was capable of understanding the general condition of the airplanes, connecting it to the airworthiness directives, and concluding that immediate, large-scale action was needed. To the mechanics and inspectors who hadn’t been trained on what a properly maintained airplane was supposed to look like, the deterioration’s very ubiquity would have made it seem normal.

But even if the airline had no one capable of connecting the dots, the FAA and Boeing certainly did. Indeed, Boeing had been aware of the shocking condition of Aloha Airlines’ fleet since at least October 1987. That month, a team of Boeing inspectors visited Aloha Airlines as part of a program designed to follow up on aging airplanes. Following its inspection, Boeing informed Aloha Airlines that it was concerned about the number of patches and the scale of the corrosion on the fuselages of several of its 737s, and advised the airline to put the planes out of service for 30–60 days in order to “totally strip and upgrade the structure.” The report made a number of recommendations intended to address the problem, and by the time of the accident some had been implemented, but the airline never did follow the manufacturer’s advice to take the planes out of service for major repairs.

The FAA, on the other hand, was largely oblivious to the scale of the problem. Primary responsibility for ensuring that Aloha Airlines’ maintenance program complied with air safety regulations fell to a local FAA Principal Maintenance Inspector, or PMI, but this particular PMI was also responsible for eight other air carriers and seven maintenance bases scattered across the Pacific basin, from Hawaii to Singapore to the PRC. This workload was too much for one person, and as a result he visited Aloha Airlines infrequently. His visits usually fell after maintenance work had been completed, so he rarely saw mechanics and inspectors in action. In fact, upon his appointment to the post in 1987, his predecessor had bequeathed to him the naïve impression that Aloha Airlines’ planes were in good working order, and he was completely unaware that the airline operated several of the highest-cycle 737s in the world. He did find some deficiencies in the way the program was organized, reporting that it “lacked depth” and that the management culture needed modernization, but he never caught on to the fact that the some of the 737s were literally falling apart out of neglect.

The FAA as a whole had taken steps to make sure that aging airplanes were given due care and attention, but the specific problem experienced by Aloha Airlines had managed to slip through the proverbial cracks. The airline was participating in the FAA’s mandatory Supplemental Structural Inspection Program (SSIP), introduced in 1981 to add extra structural checks for older airplanes, but bizarrely, these checks did not apply to the fuselage skin. This was because the SSIP was designed to target structural elements whose failure characteristics would compromise the plane’s structural integrity. The fuselage skin was not placed in this category because Boeing believed that deterioration of the skin would become obvious well before it escalated to the point of failure, and even if it did fail, the tear straps would contain the damage. Unfortunately, Aloha Airlines flight 243 proved that these assumptions were incorrect.

Because of its inadequate supplemental and regular inspections, Aloha Airlines never reported any significant airworthiness findings to the FAA, which gave the agency the false impression that everything was fine. Earlier in the 1980s, the FAA even approved Aloha Airlines’ request to extend its D-check interval from 11,000 to 15,000 hours on the basis of this supposed lack of problems. The decision to split the D-check into multiple blocks was also approved on the recommendation of the PMI without any analysis. The damning report produced by the Boeing inspectors in October 1987 could have shed light on the situation, but not only was Boeing not required to share the report with the FAA, the company actually blocked the PMI from attending the meeting in which it presented its findings, citing customer-client privileges.

The FAA only began to catch wind of a problem in December, when an inspection team working on behalf of the agency’s National Aviation Safety Inspection Program (NASIP) visited Aloha Airlines. The NASIP inspection was mostly focused on the airline’s documentation and manuals rather than its actual maintenance practices, but even so, the team’s report concluded that Aloha Airlines management had “fallen short of being able to accomplish its obligation for compliance of the [Federal Aviation Regulations], particularly in the area of Continuing Analysis and Surveillance, and Maintenance Reliability.” The inspection did not intend to verify whether the airplanes were safe, and it resulted in no commentary on their airworthiness. But despite finding that Aloha Airlines was falling short of regulatory requirements on an organizational level, no enforcement actions were taken because the inspectors judged the regulations themselves to be too subjective to form the basis for a legally justifiable intervention. As a result, the FAA essentially let Aloha Airlines continue running a clearly substandard maintenance program without any consequences.

In this respect, the regulations themselves left much to be desired. Not only were they too open to interpretation, many of them hadn’t been updated in decades and reflected the realities of an earlier era. There was no way to hold PMIs accountable for their performance; in fact the PMI for Aloha Airlines basically rubber-stamped anything the airline asked for, and no one higher up noticed or cared. Even more absurd, FAA-approved training programs for maintenance technicians still required them to have knowledge of wood airframes and airframe fabric repair, but made no mention of composites or computers. The cumulative effect of these poorly worded, outdated, and byzantine regulatory minefields was that neither airlines nor FAA employees fully understood what was required of them. In the end, it took a 737 losing its roof and the death of a flight attendant to reveal the scale of the problem.

As the NTSB pieced together this wide-ranging and tragic story, it became clear to the entire industry that major changes were needed. In fact, beginning the day after the accident, the FAA issued several ADs mandating emergency inspections of Boeing 737s, which turned up 49 findings of cracks and corrosion from 18 operators, including 14 airplanes that had particularly extensive damage. More ADs followed, all of which were aimed at resolving the problem with early 737s by mandating actions that would end the corrosion and fatigue, rather than relying on airlines to control the degradation by means of inspections. The FAA formalized this policy in June 1988 at its Conference on Older Airplanes, which served as the launch pad for a new program of not just inspecting older planes, but actively requiring the extensive replacement or modification of structures judged to be problematic in service, prioritizing solution-oriented actions over palliative measures. The FAA also introduced the Aging Fleet Program, through which FAA inspectors directly watch mechanics as they carry out corrosion control measures and structural inspections on aging airplanes.

Aloha Airlines, in addition to scrapping several airplanes, overhauled its maintenance program, including through the creation of numerous qualified positions in quality control and engineering, and by ending the practice of splitting major inspections. On top of this, the NTSB issued 21 recommendations, including that FAA maintenance inspectors receive updated training to help them evaluate airlines’ maintenance programs; that maintenance schedules reflect how much use a particular airline’s planes are actually getting; that maintenance inspectors receive formal certifications and periodic refresher training; that new corrosion control programs be developed; that accountability for the quality of inspections be improved; and that all existing and future fuselage designs be subjected to full-scale fatigue testing to at least twice their expected service lives, among many other proposals, most of which were implemented.

As a result of this revolution in the way we maintain older airplanes, it is unimaginable today that an airline in the United States would allow its planes to fall into such a sorry state of disrepair. The innovations spawned from this accident took their time to circle the globe — they failed to reach Taiwan in time to prevent the catastrophic breakup of a China Airlines Boeing 747 in 2002 — but as of 2021, there are few, if any, places that these practices have not penetrated. In fact, the China Airlines accident was the last fatal structural failure of a passenger jet. And despite fears that this system might be unsuitable for newer generations of composite-body aircraft, so far these planes have had exemplary service records, and there’s no reason to believe that they will cause a return to the days of unchecked structural degradation.

Today, Aloha Airlines flight 243 is remembered by the general public not so much for the immense safety improvements which it inspired, but for the drama of the emergency and its miraculous outcome. The events of that day have inspired multiple movies, books, and documentaries, which have helped to mythologize the accident and cement its place as one of the most memorable incidents in commercial aviation. A generation of children, having seen TV coverage of the accident or its Hollywood adaptation, have since grown up with a rather irrational fear of being sucked out of a plane in flight. And yet the outcome also testifies to the resilience of both the airplane and its crew. Flight 243 landed with no roof or walls in first class; five broken floor beams; damaged leading edges on the wings, tail, and stabilizers; debris in the engines; and the failure of an engine control cable. The oxygen system was broken; the air conditioning system was gone; water was leaking everywhere; dozens of circuit breakers had popped; wires were flailing in the open air. It was undoubtedly the most badly damaged airliner ever to make a successful emergency landing. And yet it held together until the end, giving Bob Schornstheimer and Mimi Tompkins just enough time to save the lives of 94 people, a beautiful combination of skill and luck that some might call a miracle.

_______________________________________________________________

Join the discussion of this article on Reddit!

Visit r/admiralcloudberg to read and discuss over 200 similar articles.

You can also support me on Patreon.