A Mathematical Miracle: The story of Air Canada flight 143, or the Gimli Glider

On the 23rd of July 1983, one of the greatest moments in Canadian aviation took place in rural Gimli, Manitoba, as a powerless Boeing 767, out of fuel and out of time, came in for a make-or-break emergency landing on a decommissioned runway turned drag strip. As weekend racers watched in disbelief, the wide body jet came sliding to a stop in a cloud of smoke, straddling the center divider, miraculously in one piece. Sixty-nine passengers and crew disembarked without a single serious injury. The pilots became instant heroes, as did the plane itself, which would fly for another 25 years under the nickname “Gimli Glider.” But how could a brand new Boeing 767 flown by two experienced Air Canada pilots have simply run out of fuel? The story of how flight 143 took off without enough fuel to start with has been retold many times, but usually incorrectly. What is often boiled down to a mistake converting between metric and imperial (never mind that it was actually a conversion between metric and metric) was in fact a complex sequence of communication errors and poor decisions which began at the highest levels of Air Canada and culminated in the dispatch of an airplane that never should have left the ground.

◊◊◊

In September 1982, the first Boeing 767 entered service with United Airlines, marking the arrival of a new era for America’s largest aircraft manufacturer. The 767 was Boeing’s first wide body twin-engine jet, and its first wide body jet to feature a two-crew cockpit, eliminating the flight engineer. Over the protests of certain pilots’ unions, the third crewmember had been replaced by a bank of computers, a step made possible by the breakneck pace of technological progress in the field of avionics. Some countries, such as Australia, nevertheless insisted that the 767 must have a flight engineer, but most recognized that the third crewmember was unnecessary. Among the latter group was Canada, whose flag carrier ordered 12 Boeing 767s in a two-crew configuration, with deliveries planned throughout 1983 and 1984.

By July 1983, four of Air Canada’s 767s were already in service, including one registered as C-GAUN, which rolled off the assembly line earlier that year and was delivered in March. It was an unremarkable airplane in every respect, with nothing to foreshadow its future stardom.

On the evening of July 22nd of that year, C-GAUN arrived in Edmonton, Alberta following a flight from Toronto and parked on the apron for the night. During the stopover, a technician boarded the plane to conduct routine checks and rectify any mechanical discrepancies, ensuring that the plane was in good working order before its next round of flights in the morning. But upon inspecting the cockpit, the technician found that something was amiss: despite the fact that the power was on, the plane’s three fuel gauges were blank.

The 767’s fuel gauges, located on the overhead panel between the two pilots, display the weight of the fuel in the plane’s left, right, and center fuel tanks. Sensors in the tanks measure the amount of fuel and transmit this information to the central fuel quantity processor, a computer which converts the sensor readings into the various units required by other aircraft systems, including the fuel gauges. This information is processed and transmitted to the gauges via two redundant data channels, designated channel 1 and channel 2, either of which is capable of supplying the data by itself should the other fail. It was therefore quite out of the ordinary for the fuel gauges to go blank, since any single failure in either channel should not affect their ability to display the fuel quantity. Nevertheless, Conrad Yaremko, the technician in Edmonton, had seen this type of failure before, on an Air Canada 767 two weeks earlier, on July 5th, and he remembered what he had done to fix it.

Using the system’s built-in test equipment, or BITE, Yaremko was able to discover that there was a fault with channel 2 of the fuel quantity processor. For whatever reason, this was causing the gauges to go blank when it should not have affected their operation. But like he did on July 5th, Yaremko managed to solve the problem by pulling the circuit breakers for both channels, then resetting the breaker for channel 1 only. With the faulty channel 2 now offline, the data passed through channel 1 without any problems, and the gauges blinked back to life. There was clearly a problem with the processor, which Yaremko felt needed to be replaced, but none were in stock, so the replacement would have to be deferred. Yaremko therefore slipped a paper tag around the popped channel 2 circuit breaker, placed a “see logbook” placard above the fuel gauges, and wrote in the technical log, “I001 — @ SERVICE CHECK — FOUND FUEL QTY IND. BLANK — CH 2 @ FAULT — FUEL QTY 2 C/B PULLED & TAGGED — FUEL DRIP REQ’D PRIOR TO DEP. SEE MEL 28–41–2.”

The reference to “MEL 28–41–2” invoked the relevant chapter of the plane’s Minimum Equipment List, or MEL — a document kept aboard the aircraft which lists the systems which must be operable in order to depart, and provides instructions for additional safety measures to be taken when certain systems are not working. In the case of the fuel quantity indicating system, it was permissible to fly with one processor channel inoperative, as long as the gauges were working, and as long as a manual check of the fuel levels was performed to make up for the loss of the redundancy once provided by the second channel. The entry in the logbook would remind subsequent crews that this MEL provision was in effect until such time as a replacement processor could be procured.

When the next flight crew arrived the following morning, Yaremko was still on duty, and he was able to brief the incoming Captain John Weir about the nature of the problem. It was during this conversation that the first in a long series of misunderstandings occurred. Although almost everything was conveyed correctly, Weir walked away from the conversation with the mistaken impression that the plane had been flying in this condition since it left Toronto the previous day, when in fact the fuel gauge problem only appeared on the ground after it arrived in Edmonton.

Captain Weir and his First Officer subsequently flew the plane to Ottawa, and thence to Montreal, without any problems. At each stop, the pilots and ground engineers worked together to perform a manual “fuel drip” test to double check the amount of fuel in the tanks, and each time no discrepancies were observed. Weir’s shift ended at Montreal’s Dorval International Airport, and together with his First Officer, he walked out to the parking lot, where he met the incoming Captain Robert “Bob” Pearson, who was to take over flying C-GAUN for the rest of the afternoon. It was during this conversation in the parking lot that a second misunderstanding occurred.

What exactly was said during this discussion was a matter of some dispute, but Captain Pearson got the impression that not only had the fuel gauge fault been present since the plane left Toronto on the 22nd, but that the gauges themselves had been blank throughout this period as well. Weir also mentioned that the manual “drip test” was required to verify the amount of fuel — presumably he meant that it was required by the MEL, but in line with his earlier misunderstanding, Pearson believed that this was the only way Weir had known how much fuel was on board. As a result, he was expecting to see blank fuel gauges when he boarded the airplane.

Meanwhile, a ground engineer, Jean Ouellet, was sent by Air Canada dispatch to perform the fuel drip test before C-GAUN’s next scheduled departure. Upon arriving, he noted Yaremko’s log entry, as well as the pulled circuit breaker. He had recently undergone training on the fuel quantity processor, and he immediately suspected that there was more to the issue than a fault in channel 2 — after all, if only one channel was broken, why had the fuel gauges been found blank in Edmonton? In order to check Yaremko’s diagnosis, he pushed back in the channel 2 circuit breaker, which immediately caused the fuel gauges to go blank. He then performed the BITE test, which again indicated a fault. Like Yaremko, he decided that the processor needed to be replaced, but found none in stock. Pulling out the logbook, he wrote, “FUEL QTY. IND. U/S SUSPECT PROCESSOR UNIT AT FAULT P.N. 28–40–563 NIL STOCK.” But before he could get any farther, he was called back out of the aircraft to help perform the drip check — in the process, forgetting to return the circuit breakers to their original positions. When Captain Pearson and his First Officer Maurice Quintal arrived in the cockpit minutes later, they found the fuel gauges blank, which was, coincidentally, exactly what they had expected.

Upon reviewing the logbook, Pearson noticed Yaremko’s entry, which stated “FOUND FUEL QTY IND. BLANK.” There was nothing in the entry to alert him to the fact Yaremko got the gauges working again before the plane departed Edmonton. According to Pearson, he then consulted the MEL entry indicated by Yaremko, and found that it prohibited dispatch of the airplane unless at least two of the three fuel gauges were working. But if that was really the case, how had the plane flown from Toronto to Edmonton to Ottawa to Montreal with no working fuel gauges, as he incorrectly believed it had done?

At this point, the pilots and the ground engineers began the drip stick test to ascertain how much fuel was actually in the tanks. This required pulling out a “stick” in the underside of each fuel tank, which would indicate the depth of the fuel in centimeters. Using a table of figures provided to the maintenance personnel, this value could then be converted into a volume in liters, the unit used by the fuelers. A further conversion from liters to kilograms would then be required to provide the fuel quantity to the pilots, who were much more concerned with the weight of the fuel than its volume.

This system was somewhat unique in that every other type of airplane in Air Canada’s fleet used different units. Everything except the 767s had fuel gauges which read in pounds, and the drip sticks on other Air Canada planes variously read in inches, US gallons, and Imperial gallons, depending on the aircraft type. The 767s were the first entirely new model to enter service with the airline since Canada officially began its transition from Imperial to metric measurements in the late 1970s, and the Canadian government, which owned Air Canada, had more or less insisted that 767s be ordered with metric gauges wherever international standards called for them. In practice, of course, this meant very little — in fact the only systems on the plane which were metric were the fuel gauges and the fuel drip sticks. This was consistent with industry practice in most of the Western world, where the use of early standards developed in Britain and the United States has led to the near-universal acceptance of feet, nautical miles, and knots as the default measurements of altitude, distance, and speed in aviation. At that time only China and the Soviet Union used metric units for these measurements, and this is still the case today. But international standards did call for the use of metric units when measuring aircraft weight and fuel quantity, so Air Canada began its transition to metric, such as it was, by ordering the 767s with metric fuel gauges which read fuel weight in kilograms.

Under normal circumstances, the conversion from liters to kilograms — or to pounds — and back again would be performed automatically by the flight computer. In fact, the only time an engineer or a pilot would have to do this by hand was during a fuel drip check, which would only occur if there was a problem with the fuel quantity indicating system. At Air Canada, neither flight crews nor ground engineers had been trained to do these calculations, nor was it clear who was responsible in the first place.

Nevertheless, the first part of the drip check went off without a hitch — after pulling out the sticks, measurements of 64 centimeters and 62 centimeters were obtained for the left and right wing tanks, respectively. The center tank was empty, which was normal on domestic flights. The two ground engineers, Jean Ouellet and Rodrigue Bourbeau, then consulted the conversion table and arrived at figures of 3,924 and 3,758 liters for the two tanks, adding up a total of 7,682 liters of fuel on board the plane.

Now someone needed to convert this figure into kilograms so that the pilots could calculate how much fuel they would need to add for their next trip, which was to be flight 143 to Ottawa and Edmonton. On the recommendation of Captain Weir, Pearson intended to uplift sufficient fuel to fly all the way to Edmonton, for which he calculated he would need 22,300 kilograms. To arrive at the amount of fuel which he would need to request from the fuelers, he needed to subtract the amount already in the tanks from the total of 22,300 kg. But how many kilograms were there in 7,682 liters of fuel? Nobody knew offhand how to find out, so they decided to ask the fueler for the conversion factor. The fueler replied that according to his documentation, the conversion factor was 1.77.

There was just one problem: this was the conversion factor between liters and pounds, not liters and kilograms. In fact, the fueler believed that all Air Canada planes read fuel quantity in pounds, and he had not been told that the 767s — and only the 767s — measured fuel in kilograms. He didn’t normally need to know this, since his job was to pump fuel until the pilots told him to stop. Likewise, the pilots and ground engineers were unaware that the fueler had just given them the wrong conversion factor, and assumed that the fueler meant that one liter of fuel weighed 1.77 kilograms, when it actually weighed 1.77 pounds. A little bit of critical thinking would have set off alarm bells — after all, fuel is less dense than water, and one liter of water weighs one kilogram, so logically one liter of fuel should weigh less than one kilogram. Indeed, the proper conversion factor was approximately 0.8. But for whatever reason, nobody picked up on this discrepancy.

Armed with what he thought was the proper conversion factor, ground engineer Bourbeau attempted to multiply 7,682 by 1.77 using longhand multiplication on a piece of paper, but he soon became bogged down in the numbers. While First Officer Quintal tried to help him, engineer Ouellet also attempted several times to do the math independently, but gave up after he ran out of paper. After much wrangling, Quintal and Bourbeau eventually arrived at an answer: there were 13,597 kilograms of fuel on the plane, or so they thought. Captain Pearson double checked the calculations on his mechanical calculator just to be sure, and he confirmed them to be correct. Indeed, their math was right, but the units were wrong: the fuel on board weighed 13,597 pounds, not 13,597 kilograms.

Unaware of this massive error, Captain Pearson subtracted 13,597 from 22,300 to arrive at a figure of 8,703 additional kilograms of fuel needed for the trip to Edmonton. Since the fueler needed to know how many liters to put in, the crew then converted 8,703 kilograms back into liters. Using the same wrong conversion factor again, they divided 8,703 by 1.77 to arrive at a required fuel volume of 4,916 liters. This figure was then given to the fueler, who, after obtaining the flight crew’s agreement, rounded it up to 5,000 liters and pumped the requested fuel into the tanks.

Of course, the numbers “8,703” and “4,916” were actually meaningless, because they were obtained by subtracting pounds from kilograms, which cannot be done. In fact, a pound is slightly less than half of a kilogram, so the original fuel load was actually about half of what they calculated it to be. This caused them to arrive at a required additional fuel load half the size of what was actually needed, which they then divided by the wrong conversion factor again, compounding the mistake a second time. The result was that the fueler added less than a quarter of the fuel required — they actually needed about 20,200 additional liters, not 5,000. And after accounting for the fuel which was already in the tanks, they ended up with a total of 10,146 kilograms of fuel on board, out of 22,300 kilograms required for the journey. The math actually works out very nicely to show that 10,146 kilograms is equal to 22,300 pounds. They had the “right” amount of fuel, just in the wrong units.

This discrepancy would have been obvious if the fuel gauges were working, but they were not. And while the MEL clearly stated that departure without working fuel gauges was prohibited, nobody seemed to be acknowledging this fact. Pearson would later argue that a mechanic told him that the plane was declared fit for service by Maintenance Central, while the rest of those present, including First Officer Quintal and engineers Ouellet and Bourbeau, did not mention having discussed the contents of the MEL at all. In any case, regardless of what was said or not said, Pearson had gotten the impression that the plane had been flying without fuel gauges since yesterday, and that if this was the case, then somebody with more authority than him must have authorized it. Everyone else apparently went along with this without question.

By the time all was said and done, Air Canada flight 143 pushed back from the gate with half the required fuel, no working fuel gauges, and two pilots blissfully unaware that they were making a colossal mistake.

Nevertheless, the plane had enough fuel to reach Ottawa, which it did without incident. Some passengers disembarked, others boarded, and a mechanic fiddled with the fuel gauges again. He pulled the fuel processor channel 2 circuit breaker, observed no change, and put it back. The crew also conducted another fuel drip check, as was required. This time, the fuelers gave them a conversion factor of 1.78, the difference of 0.01 presumably being down to the local temperature. This conversion factor was still wrong for all the same reasons as before, and once again, the crew did the correct math using the wrong constants, arriving at a fuel total which was completely incorrect but was more or less what they expected. At last, now with 61 passengers and 8 crew aboard, flight 143 left Ottawa, bound for Edmonton, her pilots still unaware that they did not have enough fuel to get there.

For some time, flight 143 cruised normally above Ontario and into Manitoba, slowly burning through its fuel reserves until it was running on fumes. Normally a low fuel warning would have illuminated to warn them when they had 45 minutes of fuel left, but it never came on, because the warning system received its fuel quantity information from the same faulty processor as the fuel gauges. Cruising at 41,000 feet, conversing with an Air Canada engineer about the systems on the new 767, the pilots had no idea that they were minutes away from running dry.

It therefore came as a complete surprise when the left fuel pump, already sucking on air, threw out a low fuel pressure warning as the plane passed over eastern Manitoba. Once the warning came on, however, the reason must have been self-evident: given their inoperative fuel gauges and the difficulties calculating the fuel load, the most sensible cause for the warning was a lack of fuel. This was confirmed moments later when the independent right-hand fuel pump also produced a low fuel pressure warning.

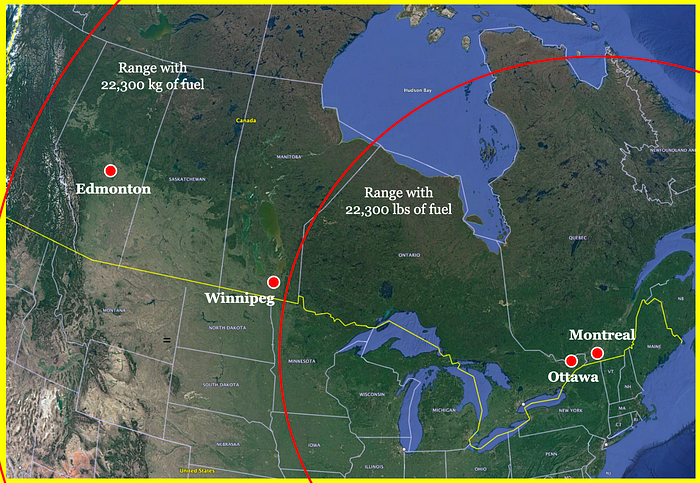

Recognizing that he was facing a serious emergency, Captain Pearson immediately decided to divert to the nearest major airport. In this part of the country, that could only be Winnipeg — other options were decidedly limited, given that the terrain underneath the plane consisted of empty Canadian Shield, followed by the mighty expanse of Lake Winnipeg, neither of which offered much in the way of airports or runways. With that in mind, the pilots apprised air traffic control of their intent to divert to Winnipeg, secured permission to turn south toward the airport, and began a relatively sedate descent from 41,000 feet.

Unfortunately, the illusion of control didn’t last long. The pilots had barely begun the diversion when the left engine, starved of fuel, abruptly flamed out. Shortly thereafter, with the plane still 65 nautical miles from Winnipeg and descending through 35,000 feet, the right engine followed suit.

Barely five minutes after the first sign of trouble, Captain Pearson and First Officer Quintal found themselves in a nearly unprecedented emergency. In 1983, there was no prescribed procedure for flying and landing without any engines. To make matters worse, the lack of fuel necessarily precipitated a near-total loss of electrical power, which blanked out most of the pilots’ instruments. All that remained were a few basic analog backups: a standby attitude indicator, an altimeter, an airspeed indicator, and a magnetic compass. The situation would have been even worse were it not for the deployment of the Ram Air Turbine, or RAT, a small propeller which, in the event of a dual engine failure, automatically drops into the airstream below the plane, where it generates power to keep the hydraulic pumps running. Without it, the pilots would be unable to move the 767’s massive control surfaces.

An airliner without engine power will descend at a fairly controllable rate all on its own — the much more difficult part is nailing the landing. Gliding a jet down to a powerless, or “dead-stick” landing requires a great deal of precision, since only one approach can be attempted, and a continuous descent must be made all the way to the runway with no possibility of leveling off. Circling to land is also difficult, if not impossible, because making tight turns without engine power can easily lead to a stall. These realities had trapped some crews who previously attempted to land large airplanes without engines. The range of a gliding aircraft is constantly narrowing, and a smart decision about a landing site must be made early enough to leave sufficient time to line up with the runway without inadvertently committing to a destination which is too far away. Southern Airways flight 242, for instance, which lost both engines in a hailstorm over Georgia in 1977, was forced to land on a highway after the pilots spent too long heading for an airport which was out of range. A catastrophic crash ensued, killing 72 people. To avoid the same fate, Pearson and Quintal needed to learn their options and make a wise decision as quickly as possible.

As far as they were aware, however, they would have only two options to choose from. On the one hand was Winnipeg, 65 miles distant, with long, well-maintained runways and a full complement of emergency services. On the other was a decommissioned military airbase in the town of Gimli, some 45 miles from their position, near the shores of Lake Winnipeg. Suggested as a potential landing site by First Officer Quintal, who had once served there in the Royal Canadian Air Force, Gimli’s present status was a total unknown. It had two 7,200-foot runways, much shorter than those in Winnipeg; no assurance that those runways were being maintained; and no emergency services that air traffic control was aware of. Its one advantage was that it was closer. The question, then, was whether distance would be the limiting factor. They had only a matter of minutes to decide before they would be forced to commit to one airport or the other.

The problem now faced by the crew was that they had no direct indication of their descent rate. The vertical speed indicator had ceased operations along with most of the other instruments, forcing First Officer Quintal to instead calculate their descent angle manually using their altitude and the distance from Winnipeg across several regular intervals. While Captain Pearson held the plane at a steady 220 knots, Quintal repeatedly asked ATC for their distance from Winnipeg, noting their altitude at the time of each request. With a little bit of basic arithmetic, he was able to determine how many feet of altitude they were losing per nautical mile, and, by extrapolating this trend into the future, estimate their remaining range. By the time he had finished his calculations, they were 33 miles from Winnipeg and 12 miles from Gimli. And by his estimate, they could only glide another 20 miles, perhaps less. The pilots immediately made their decision and reported it to ATC: flight 143 was diverting to Gimli. Winnipeg International Airport was visible in the distance, hovering tantalizingly on the horizon, but it was now forbidden to them, and they had no choice but to turn away.

◊◊◊

Meanwhile in the cabin, the 61 passengers, scattered throughout the mostly empty 767, prepared for the worst. Having at first been told that they were diverting to Winnipeg because of a technical problem, the passengers realized the true seriousness of the situation only when both engines suddenly rolled back, leaving the cabin eerily silent. Convinced that they were going to crash into Lake Winnipeg, some passengers began writing wills or notes to loved ones on any scrap of paper they could find. The flight attendants did their best to prepare the cabin, instructing passengers on emergency procedures, although they themselves had no idea what to expect. They certainly could not have imagined the bizarre series of events which was about to unfold.

Back in the cockpit, the pilots made their final adjustments for the imminent emergency landing. After completing a sweeping turn to the right, Gimli airbase hove into view, just beyond the sandy shores of the lake. Notably, the RAT didn’t power non-essential controls such as the flaps and slats, which increase lift and enable low-speed flight, so Pearson knew they would have to come in hot. What he did not expect was that the RAT didn’t provide power to the landing gear actuators either. Moments from landing, Quintal attempted to lower the landing gear, but when he pulled the gear lever, nothing happened. Thinking quickly, he reached for the alternate gear extension switches, which bypassed the hydraulic system to lower the landing gear in free fall, also known as a “gravity drop.” Upon flipping the switches, the heavy main landing gear successfully deployed with a loud clunk, but the nose gear did not.

At around this time, Captain Pearson began to realize that they were coming in too high. If he didn’t lose altitude fast, they would overshoot the airport entirely. But if he put the plane into a steep descent, it would gain too much speed, and they wouldn’t be able to stop on the relatively short runway. They needed some way to bleed off their excess height without increasing their speed. One way to do this would be to make a 360-degree loop, but Quintal could tell at a glance that with their current descent rate, it was already too late to complete one — they would strike the ground before making it back to the runway.

It was in this moment that Captain Pearson earned his stripes. A glider pilot in his spare time, Pearson was familiar with various techniques for controlling unpowered aircraft, including a particularly choice maneuver called a forward slip. (A more extensive discussion of slips can be found in my previous article on Airwork flight 23.) A slip can be induced on any aircraft by steering the nose in one direction with the rudder, while banking in the opposite direction with the ailerons to compensate. This allows the plane to maintain its present course while skidding or slipping with one side facing into the oncoming air and the forward wing pointed at the ground. Pointing the side of the fuselage into the airstream in this manner generates enormous drag which will cause the plane to descend while also keeping its forward airspeed in check. This was exactly what Pearson needed. Informing Quintal that he was going to “slip it,” Pearson crossed his controls, steering hard right with the rudder and hard left with the ailerons. The nose swung out to the right and the wings banked sharply to the left, sending the plane into a terrifying forward slip. Passengers seated on the left side of the aircraft stared directly at the ground as, per Quintal’s recollection, Pearson held the plane at a bank angle considerably in excess of 45 degrees.

As he held the plane in the slip, Captain Pearson’s world narrowed until nothing remained save for himself, the runway threshold, and the controls in his hands. Flying by feel, he increased and decreased the amount of slip in a continuous effort, manhandling the plane onto a trajectory which would place it inside the touchdown zone. He was so focused that he didn’t even realize that the nose gear was not down, and that Quintal was frantically flipping through the Quick Reference Handbook, or QRH, in search of the manual gear extension procedure. And it was only now, seconds before touchdown, that they suddenly looked up and realized that they had much bigger problems than a faulty nose gear: in fact, their runway was no longer a runway at all.

Unbeknownst to Quintal, the former airbase now served a dual purpose: one runway was kept operational for use by a local flying club, while the other had been turned into a drag strip. Unable to see the racing equipment from far away, the pilots had inadvertently lined up with the drag strip instead of the runway. And to make matters worse, today was Saturday — race day at the Gimli Motorsports Park, and the Winnipeg Sportscar Club was out in force. Car enthusiasts were camped out all along the side of the runway and across its far end, directly in the path of the airplane. But there was no turning back now — Pearson had no choice but to put the plane on the ground and hope the gearheads got out of the way!

At the last moment, Pearson pulled out of the slip and planted the wheels on the runway, landing perfectly inside the touchdown zone, traveling at a speed of over 300 kilometers per hour. He immediately lowered the nose and slammed on the brakes, only for the partially extended nose gear to collapse backward into its wheel well. The nose slammed onto the runway with a sound like a gunshot, followed by more sharp blasts as two tires burst under Captain Pearson’s heavy braking. He had no choice but to put the pedals to the floor, because directly ahead of him were two young boys on BMX bicycles, out riding on the drag strip, who had suddenly found themselves in the crosshairs of a speeding Boeing 767. As humans are wont to do, their instinct was to try to outrun the plane rather than dodging to one side, forcing Pearson to brake even harder. It was at that moment that the 767’s nose finally slammed into the guard rail dividing the two lanes of the drag strip, and with a jolt followed by much infernal scraping, the plane finally ground to a halt, straddling the center divider with its nose on the ground. The pilots and passengers alike could hardly believe it — against all odds, flight 143 had landed without putting a scratch on anyone.

Although the worst of the danger was past, a number of factors complicated the evacuation, not least among them a smoldering fire under the cockpit, where sparks had ignited insulation material. Smoke from the fire quickly filled the front of the aircraft, where fortunately very few people were seated. However, when flight attendants opened the rear emergency exits, they found that the tail was so high in the air that the slides didn’t touch the ground. Sliding down them was less like schoolyard fun and more like jumping off the second or third floor of a building. Many passengers elected to use the overwing exits instead, even though the slides there were never deployed, since the flight attendants apparently did not know where they were — the accident in fact predated comprehensive aircraft conversion training for flight attendants in Canada, and they were more used to the exit configuration on the 747.

Despite the setbacks, however, the evacuation proceeded with only 10 minor injuries, and members of the sportscar club were able to quickly put out the fire using extinguishers set aside for the race. Emergency services soon arrived from the town of Gimli, but to their great relief, there was little for them to do — nearly everyone was fine.

◊◊◊

The sensational emergency landing in Gimli immediately made national and international headlines, dominating Canadian news networks for weeks. Captain Pearson and First Officer Quintal were hailed as heroes, even more so after information emerged about Pearson’s actions in the moments before touchdown, which were so instrumental in the outcome. It was a story which seemed to be Hollywood-ready, with so many grandiose details and twists of fate and fortune that it in fact made for rather campy, melodramatic cinema, as moviegoers discovered when the events of flight 143 were adapted to the silver screen in 1995. Regardless, however, Captain Pearson had secured a place among Canada’s greatest aviators, and the plane, now known as the Gimli Glider, among its most famous aircraft. But retellings too often end here, with the miracle landing and the hero pilot who pulled it off. Members of the public are thus frequently surprised to discover that neither Pearson nor Quintal was lauded by Air Canada, and in fact Pearson was demoted for six months, while Quintal was suspended for two weeks. The first response to this discovery is sometimes outrage. But there has always been another side to the story of the Gimli Glider, one which does not necessarily diminish the impressiveness of the emergency landing, but does undermine the narrative which has since been constructed around it.

◊◊◊

The primary investigation into the crash was led by a specially assembled Commission of Inquiry, headed by the Honourable Justice George H. Lockwood. In contrast to modern practices, his inquiry was both a safety investigation and a criminal investigation, as Lockwood possessed the power to recommend prosecution of anyone involved. In the end, he declined to do so, but he did take the time to point out that serious mistakes were made prior to the departure of flight 143, and in fact most of his final report was spent discussing these, with only cursory detail afforded to the events of the flight itself.

Lockwood also took pains to dispel the popular notion that the crash was caused by a “metric mixup,” writing that the metric system had nothing to do with it, nor was anyone trying to convert from metric to Imperial or vice versa. The use of the wrong conversion factor occurred without anyone ever being particularly confused about units. And in any case, this was but one of several elements without any one of which the accident would not have occurred.

In Lockwood’s view, the plane ran out of fuel because three layers of redundant safety features all failed, one after another: first the fuel gauges, then the requirement not to dispatch without working fuel gauges, and finally the direct check of the fuel quantity, prescribed by the MEL. Each of these was analyzed in turn.

The failure of the fuel gauges themselves was perhaps the simplest of the three. When the fuel quantity processor was sent back to Honeywell for analysis, experts discovered a bad solder between an induction coil and its terminal block in channel 2, which resulted in a gradual breakdown of the connection between these elements. Due to a design flaw in the processor, this particular failure caused a partial loss of power to the logic circuit which was supposed to identify the fault, store the appropriate fault code in the device’s non-volatile memory, and effect the automatic transfer of the fuel quantity indications over to channel 1. As a result, the gauges continued to use the faulty channel 2, which is why they went blank even though only one of the two redundant channels had failed. The Edmonton mechanic, Conrad Yaremko, had managed to get around this problem by pulling the circuit breakers for both channels and then only resetting the breaker for channel 1, causing the system to initialize using only that channel — effectively forcing the transfer of responsibility which was supposed to have happened automatically.

The problem could have been solved on the spot if another fuel processor had been available, but none were in stock. In fact, when it purchased the 767, Air Canada had developed a spare parts plan based on expected failure rates for various components, under which they anticipated a need for only one spare fuel quantity processor for their fleet of twelve 767s. In service, however, this assumption proved hopelessly optimistic. And to make matters worse, this singular processor had been sent away to France where it was participating in the development of an aerospace computer repair program. It was still in France when the first fuel quantity indication problem appeared on C-GAUN on July 5th, also in the presence of Mr. Yaremko, although he didn’t realize this was the same aircraft until after the accident.

As a result of the failure of the fuel gauges aboard C-GAUN on July 5th, Air Canada requested the return of the fuel processor from France, but when it arrived, it was found to be faulty, and was sent to Honeywell for repairs, where it would remain until January 1984. In the meantime, C-GAUN continued to fly with its own malfunctioning processor. The unit worked fine for the next nine days, until a flight to San Francisco on July 14th. As C-GAUN neared its destination, the fuel gauges suddenly went blank, and the pilots landed in San Francisco without them. Air Canada arranged for United Airlines to supply a replacement processor in San Francisco, but before the new processor could be installed, the old one started working again, and the plane returned to Canada without any repairs having been made. It then flew for eight more days until it arrived in Edmonton on the 22nd of July, where Mr. Yaremko once again found that the fuel gauges were blank. After being informed of the problem, Air Canada requested a spare processor from Pacific Western Airlines, but they were informed that the unit would not be available in Edmonton until the following day. That was no matter, dispatch decided — the plane was going to return to Edmonton on the 23rd anyway, and the unit could be installed then.

Justice Lockwood’s report faulted Yaremko only for his failure to clearly indicate that he had solved the problem when writing his logbook entry. This was one of several items which would later convince Captain Pearson that the fuel gauges had been blank ever since the plane left Toronto the previous day. Pearson maintained that Captain Weir, who flew the plane from Edmonton to Montreal, told him as much in the parking lot. Weir denied this, and Justice Lockwood took his side. In his report, he wrote that there was no reason for Weir to have said such a thing, although it also seems that Weir could have used the word “blank” when discussing the state in which the gauges were found, and that this could have been the source of Pearson’s confusion. Regardless, Pearson told the inquiry that he was expecting blank gauges when he got to the plane, and that was what he found.

This was not the only discrepancy between Pearson’s testimony and the recollections of others who were present that day. When it came to the matter of whether the plane was legal to fly with blank fuel gauges, Pearson explained that he had looked at the MEL, concluded that they were not legal, and said as much to Quintal and the engineers. According to Pearson, one of the engineers then told him that authorization had been given by Maintenance Central to fly the aircraft in that condition. On the other hand, both Quintal and the engineers denied that this conversation ever took place. In their view, the legality of flying with blank fuel gauges was never discussed, despite Yaremko’s logbook entry which directed the pilots to examine the relevant chapters of the MEL. The only other person present who recalled looking at the MEL was one of the maintenance engineers, Mr. Bourbeau, who said he only read the section relating to the drip tests, and not the section pertaining to the gauges themselves. For his part, Bourbeau also professed a belief that the plane had been flying with blank fuel gauges since the 22nd.

Pearson told the commission that, as far as he knew, Air Canada’s Maintenance Central could override provisions of the MEL, and that this department possessed a more comprehensive “master MEL” which contained details not in the version which was carried in the cockpit. Some other Air Canada pilots expressed similar beliefs. However, this was simply not true — the MEL in the cockpit was the same as the one used by Maintenance Central, and this MEL was the final authority on whether or not the plane was legal to operate. This mistaken belief in a master MEL seemed to have come about because of a number of previous incidents in which Maintenance Central did in fact authorize the dispatch of airplanes which were not in compliance with certain MEL provisions. Although the MEL was binding in 1983, it was not binding at Air Canada before 1970, nor was it binding under Canadian law until 1977, and the relative recency of this change might have been the cause of the aforementioned incidents. The Air Canada Director of Operations Engineering testified that he knew of one to two such cases each month, and that the airline had tried to crack down on the practice using a safety video. Nevertheless, even after the accident, some cases continued to be reported in which Maintenance Central attempted to dispatch a plane which was not in compliance with the MEL.

Needless to say, even with knowledge of these previous events, Captain Pearson should still have questioned the idea that Maintenance Central would let a plane fly with blank fuel gauges. Doing so was plainly dangerous, and Lockwood was perplexed that a pilot as experienced as Pearson would accept the plane in such a condition. At the very least he should have checked with Maintenance Central himself, at which point he would have discovered that no such exemption had in fact been issued.

Having made the erroneous and frankly reckless decision to fly with blank fuel gauges, the last and most well-known mistake occurred when the crew used the wrong conversion factor to convert the fuel quantity from liters to kilograms and back again. However, this was not so much the fault of any individual as it was the fault of Air Canada as a whole. It was Air Canada’s responsibility to inform the refueling companies at its airports about the fact that its Boeing 767s measured fuel in kilograms rather than pounds, but the responsible personnel simply forgot to do so. This problem went undetected until flight 143 because the conversion factor was not normally needed except to conduct a “drip stick” test, which was only required when one fuel quantity processor channel was faulty. In normal operations, the conversion was done by the flight computer. Some fuelers had heard that the 767s measured fuel in kilograms, but not all of them. When C-GAUN stopped in Ottawa earlier that day, the fueler gave Captain Weir the proper conversion factor of 0.8, and all calculations were performed correctly. The crew of flight 143, on the other hand, were unlucky enough to get fuelers in both Montreal and Ottawa who were unaware of the distinction, and provided the conversion factor for pounds instead.

Here Lockwood had to note that while it was unclear who actually did the math, it didn’t really matter, because neither pilots nor ground engineers at Air Canada were taught how to do manual fuel calculations or how to perform drip stick tests. No one involved had ever had to convert liters to kilograms before, nor did they know how to do so. Had they looked up this matter in the manual, they would have found an unnecessarily complicated procedure which required converting to pounds first, then into kilograms, but it does not seem that this was used. In any case, someone should have been trained in the proper technique, but nobody was.

On previous aircraft types, manual fuel calculations were the explicit responsibility of the flight engineer. The 767 was only the second model operated by Air Canada which did not have a flight engineer, and it emerged that the reallocation of this responsibility was never properly completed. When writing the Air Canada Boeing 767 Flight Crew Operations Manual, Air Canada’s chief 767 pilot decided that responsibility for fuel calculations and drip stick tests in abnormal situations, formerly held by flight engineers, should fall to maintenance personnel instead. Simultaneously, however, the Senior Operations Engineer responsible for drawing up 767 maintenance procedures based his fuel-related decisions on the two-crew DC-9, where he believed fuel calculations were not the mechanics’ responsibility, but the pilots’. Somehow, these contradictory decisions were never reconciled, and the 767s went into service with both pilots and mechanics believing that drip stick tests and the associated calculations were the other’s responsibility, and without either having been trained to perform them.

Justice Lockwood noted that at most other airlines, this responsibility was explicitly given to the maintenance personnel, and those personnel were properly trained to perform the drip stick tests and the fuel calculations. The pilot who flew C-GAUN into San Francisco on July 14th even noted that United Airlines mechanics provided him with the fuel weight in kilograms without being asked, and despite never having done a drip stick test or any fuel calculations on a metric aircraft before. Air Canada could easily have ensured that its maintenance personnel were equally well trained, but the airline failed to do so.

In Lockwood’s opinion, this was but one example of the organizational dysfunction which plagued Air Canada at that time. In one rather amusing passage, he wrote that Air Canada’s management structure was too “top heavy,” with “something like 26 vice presidents,” and that it was almost impossible to make decisions in a timely manner. He also criticized the airline’s manuals, procedures, and MELs as poorly written and lacking clarity compared to those of other airlines. He did praise the maintenance department for holding daily meetings to discuss every deferred defect on every Air Canada airplane, ascertaining why each had been deferred and what was being done about it, but he noted that the meetings had a fatal flaw — they weren’t held on weekends, and flight 143 was scheduled on a Saturday.

Lockwood also felt it prudent to ask whether pilots in general knew enough about the planes they were flying. Up until the 1960s, pilots were taught a great deal about the functioning of every aircraft system, but as these systems became more reliable this knowledge became more esoteric, and the definition of what pilots ‘needed to know’ became stricter. The result was that by 1983 pilots usually didn’t know how most systems worked from an engineering perspective, especially with regard to avionics. The pilots of flight 143, for instance, certainly didn’t understand the internal architecture of the fuel quantity processor, even though such knowledge would have helped them deduce that the gauges shouldn’t be blank. Today, as in 1983, this type of knowledge is gained through operational experience, but because the 767 was so new, neither Pearson nor Quintal had any to speak of. At the time of the accident, Quintal had only 75 hours on the 767, and Pearson had no more than a couple hundred — hardly enough to gain the kind of systems knowledge which would have helped them prevent the accident.

Consequently, one of Justice Lockwood’s recommendations was to re-examine what information was included in the “need-to-know” training received by modern airline pilots. This was but one of numerous areas where Lockwood recommended improvements. He also recommended rewording several manuals and documents; standardizing the fuel weight units across the Air Canada fleet; using circuit breaker inoperative tags that would prevent the breaker from being reset; establishing a flight safety organization within Air Canada; improving fueling procedures; and quite a large number of other very detailed suggestions, of which he was pleased to note that most were already implemented by the time he published his final report in 1985.

◊◊◊

Despite Captain Pearson’s public status as a hero, Justice Lockwood strongly criticized some of his decisions, describing his departure with blank fuel gauges as perhaps explicable but neither proper nor forgivable, especially for someone of his experience. It was an act of remarkably poor judgment which, to Pearson’s likely relief, was completely overshadowed by the events which followed. It was this mistake which led to Pearson’s six-month demotion and Quintal’s two-week suspension, even as the Fédération Aéronautique Internationale granted them each a “Diploma for Outstanding Airmanship.” Furthermore, Lockwood only indirectly examined the troubling differences between Pearson’s recollection of events and that of the other pilots and engineers, which has led some to accuse Pearson of lying, although I would steer such discussion instead toward the dangers of combining safety and criminal investigations. Knowing that Lockwood possessed the power to recommend prosecution, all of those involved would have been incentivized, and probably were also advised by their lawyers, to avoid admitting any egregious errors. Without this pressure, it’s entirely possible that the testimonies given by all the pilots and engineers, not least among them Captain Pearson, would have been very different.

What, then, should be our view of the pilots of flight 143? Could it be possible that they deserved both their punishments and their awards? I would argue that the answer is yes. Others are a little more critical; the air safety blog Code7700, for instance, wrote that they perhaps deserved awards for “outstanding stick and rudder skills,” but definitely not for airmanship, since “the primary ingredient in airmanship, after all, is judgment.” Put another way, flight 143 was a case of mediocre piloting but excellent flying. And there is something to be said for that, as Pearson’s feat of technical skill is rendered no less impressive for knowing how he got there.

In the end, there is probably little use in playing up the crew’s mistakes. After all, they got the plane on the ground in one piece, no one was seriously hurt, and the damage was so light that the aircraft was repaired, returned to service, and flew for another 25 years. Even today, Gimli Glider enthusiasts — and there are many — can own a piece of the legendary aircraft in the form of a luggage tag made from its fuselage skin. As for the pilots, both learned valuable lessons and got on with their lives. First Officer Quintal eventually made captain, carried his career through to a well-deserved conclusion, retired, and passed away in 2015. Captain Pearson also returned to the left seat, flew for Air Canada for ten more years, worked a brief stint at Asiana Airlines, and retired in 1995. As of this writing he is still alive, and seems more than happy to talk about the incident that made him famous. He even made a cameo appearance in the movie based on flight 143, playing a flight instructor. And from his interviews alone, it’s hard not to like him. He is a living reminder that good people make mistakes too, and that it’s possible to redeem oneself immediately if the rebound is sufficiently legendary.

_________________________________________________________________

Join the discussion of this article on Reddit!

Visit r/admiralcloudberg to read and discuss over 220 similar articles.

You can also support me on Patreon.